About Us

Company Profile

As a member of Nisshin Seifun Group with more than 120 years of history, Nisshin Seifun Welna Inc. offers a wide range of processed food products, including wheat flour, premixes, pasta, pasta sauce, and frozen pasta. Our products are sold in more than 50 countries worldwide.

Message from

the Director and President

As a top brand manufacturer, we will continue to hone our strengths and create an organization that continues to evolve for further growth.

Takahiko Iwahashi

Director and President of Nisshin Seifun Welna Inc.

Nisshin Seifun Welna Inc. is an integrated food manufacturer offering a wide range of wheat-based secondary processed products, including flour, premixes, pasta, pasta sauce, and frozen pasta for both the household- and commercial-use markets. As the core company in charge of the processed foods in the Nisshin Seifun Group, we will remain committed to our guiding philosophies of "the basis of business is built on trust" and to "be in tune with the changing business climate" along with our corporate principle to "contribute to a healthy and fruitful life for all."

Nisshin Seifun Welna possesses three key strengths: brand power, global production sites, and technological capabilities. In January 2022, we made a new start under the name "Nisshin Seifun Welna". Under this new corporate brand, we will combine the power of our product brands, and continue to hone the strengths of each brand and thus drive further growth.

To ensure our continued growth in the future, we will strengthen three capabilities: Endurance, i.e. business continuity and sustainability, Growth, i.e. profitability and business scale, and Competitiveness, i.e. adding value to differentiate ourselves from our peers and strengthening cost competitiveness. We believe that Endurance is especially important in establishing a stable business foundation that can respond to the ever-changing environment and risks surrounding our business. Going forward, we will continue to maintain and strengthen our core business, household-use products while also investing in the overseas, frozen food, and commercial-use businesses where further growth is expected. By growing these three business areas, Nisshin Seifun Welna will transform its business structure.

We have positioned our overseas business as a key initiative within these three growth areas. By utilizing the manufacturing techniques and diverse expertise we have cultivated in Japan, we will strengthen product development and sales based on local consumer needs. We have eight subsidiaries in six countries with 14 sites, seven of which are engaged in manufacturing. Until recently, we have emphasized manufacturing and importing overseas products by leveraging our local advantages overseas. Now we are focusing on a "made and sold locally" business model and spreading the appeal of Japanese food throughout the world. As the manufacturer of leading food brands in Japan, Nisshin Seifun Welna values the customers who have supported its products to date. As such, we will continue to evolve to better meet their trust and expectations. We appreciate your continued understanding and support.

Overseas Business and Location

Tel. +66-2-324-0565

Tel. +66-2-323-0956

Tel. +1-253-846-2600

Tel. +86-532-8172-1157

Tel. +86-21-8012-9927

Tel. +86-28-6080-2319

Road 15, Long Binh Industrial Park (Amata), Long Binh Ward, Dong Nai Province, VIETNAM.

Tel. +84-251-8877-666

Tel. +84-251-3686-123

Jalan Kyai Haji Mas Mansyur, Kav.35 Karet Tengsin,

Kecamatan Tanah Abang, Kota Jakarta Pusat 10220, Indonesia

Tel. +62-21-2168-1040

Tel. +90-312-267-1800

History of Nisshin Seifun Welna

Here we introduce the history of Nisshin Seifun Welna

PT. Indonesia Nisshin Technomic begins operations, aiming to expand sales of commercial-use premixes in the Southeast Asian market.

Vietnam Nisshin Seifun Co., Ltd is established as a subsidiary to manufacture and sell heat-and-serve products (e.g., retort pouch foods, such as pasta sauce) in Vietnam.

Nisshin Seifun Welna's Approach

to Safety and Security

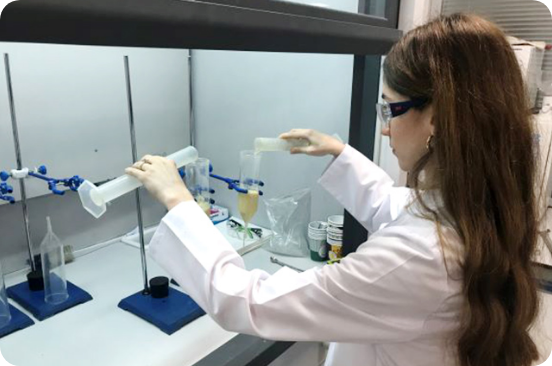

Based on our corporate mission "contribute to a healthy and fruitful life for all", Nisshin Seifun Welna places the utmost importance on providing delicious, safe, and trusted food to consumers. We strive to achieve the highest customer satisfaction by prioritizing quality assurance from their perspective, not only in product development, but also in every step along the way, from raw material procurement and production through to delivery to customers.

How Nisshin Seifun Welna products are made

-

Receipt & StorageRaw materials used are checked to ensure they meet our standards and brought to the warehouse. Flour, which is the main raw material, is delivered by trucks from the flour mill and stored in dedicated tanks.

-

Manufacturing (Mixing)Floor and other raw materials are mixed through a fine sieve

-

Packaging

Premixes are individually packaged, and all products are checked by inspection processes using weight and foreign material inspection machines.

Products that pass inspection are packed in cardboard boxes and stored in a warehouse.

-

Product InspectionBefore shipment, physical and chemical analyses, cooking and processing tests, and sensory evaluations are conducted to ensure that quality standards are met. In addition, inspection results and manufacturing records are reviewed to determine whether a product passes or fails.

-

ShippingProducts that are judged to have passed inspection will be shipped throughout Japan and to overseas.

-

Receipt & StorageDurum semolina delivered by designated suppliers is analyzed each time it is received to ensure that it meets our standards.

-

Manufacturing (mixing)Water is added to the durum semolina and the dough is kneaded evenly so that it does not have inconsistencies.

-

Manufacturing (molding)The dough is extruded through dies with many holes, which molds it into the shape of the pasta being made.

-

Manufacturing (drying)Once molded, the pasta is slowly dried while adjusting the temperature and humidity. Drying conditions are checked regularly as it is also an important process that affects the quality of the pasta.

-

PackagingThe pasta is individually packaged after being cut to a predetermined length, and all products are checked by inspection processes using weight and foreign material inspection machines. In addition, each item is visually checked for any issues with the packaging and printing condition. Products that are judged to have passed inspection are packed in cardboard boxes and stored in a warehouse.

-

Product InspectionBefore shipment, physical and chemical analyses and sensory evaluation are performed to ensure that quality standards are met. In addition, inspection results and manufacturing records are reviewed to determine whether a product passes or fails.

-

ShippingProducts that are judged to have passed inspection will be exported to Japan.

-

Receipt & StorageRaw materials used are confirmed to meet our standards and delivered to a temperature-controlled warehouse.

-

Manufacturing (Mixing)After confirming the ingredients to be used, they are cooked according to the recipe in a mixing cauldron.

-

Manufacturing (filling)Once cooked, the sauce is individually packaged, and all products are inspected for sealing and weight.

-

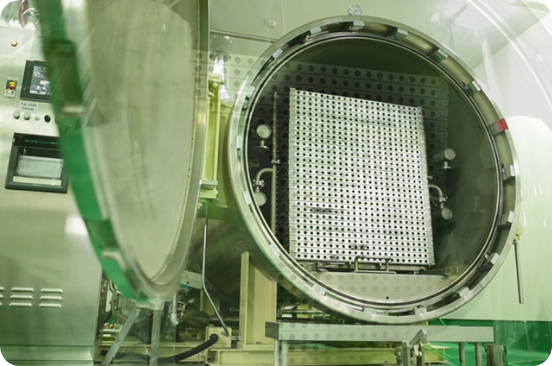

Manufacturing (sterilization)Hermetically packaged products are heat-sterilized to allow storage at room temperature.

-

PackagingAll packages are checked through inspection processes such as foreign material inspection machines. In addition, each item is visually inspected to identify any issues with packaging or printing. Products that pass inspection are packed in cardboard boxes and stored in a warehouse.

-

Product InspectionBefore shipment, physical and chemical analyses and sensory evaluation are performed to ensure that quality standards are met. In addition, inspection results and manufacturing records are reviewed to determine whether a product passes or fails.

-

ShippingProducts that are judged to have passed inspection will be exported to Japan.

-

Receipt & StorageRaw materials used are checked to ensure they meet our standards and brought to a temperature-controlled warehouse.

-

Manufacturing (sauce cooking)After confirming the ingredients to be used, they are cooked according to the recipe in a mixing cauldron.

-

Manufacturing (pasta boiling process, topping, freezing)To ensure that freshly boiled pasta can be frozen quickly, the pasta is boiled continuously, topped with its sauce, then placed directly in freezers.

-

PackagingThe frozen pasta is packaged in inner and outer packaging, and all products are checked by inspection processes using weight and foreign material inspection machines. Products that pass inspection are automatically packed in cardboard boxes and stored in a cold storage warehouse.

-

Product InspectionBefore shipment, physical and chemical analyses and sensory evaluation are performed to ensure that quality standards are met. In addition, inspection results and manufacturing records are reviewed to determine whether a product passes or fails.

-

ShippingProducts that are judged to have passed inspection will be delivered throughout Japan in temperature-controlled trucks and shipped from Japan to overseas.

Contact Us

Japanese

Japanese